Understanding Aluminium Pressure Die Casting Process

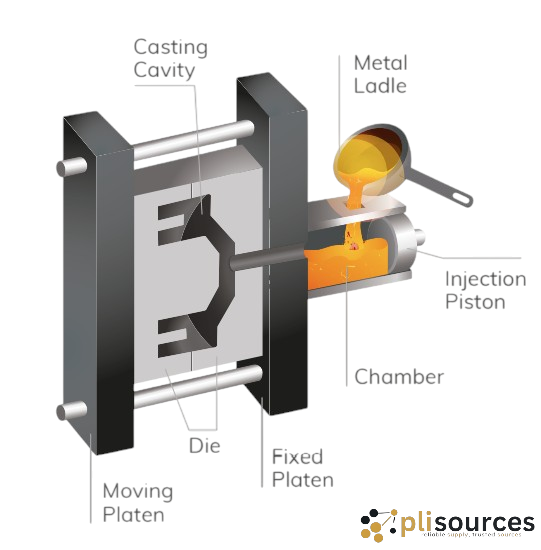

Aluminum pressure die casting is a method where molten aluminum is injected under high pressure into a mold, producing parts with high precision and smooth finishes. This process is perfect for creating complex, lightweight, and durable components quickly and cost-effectively. Steps: 1. Molten metal is accurately measured and poured into a cold chamber for each casting cycle. 2. A single plunger injects the molten metal into the die cavity through a narrow gate, applying pressures ranging from 7 to 207 MPa. 3. The die, equipped with water cooling, rapidly solidifies the metal within moments. 4. Once the metal solidifies, the dies open, and ejector pins remove the finished casting. 5. A trimming die removes the excess metal, or flash, formed where the two die halves meet, delivering a clean final product. At Plisources, we connect you with leading manufacturers in aluminum pressure die casting, ensuring you receive top-quality parts designed to meet your specific needs in a personalized and efficient manner.