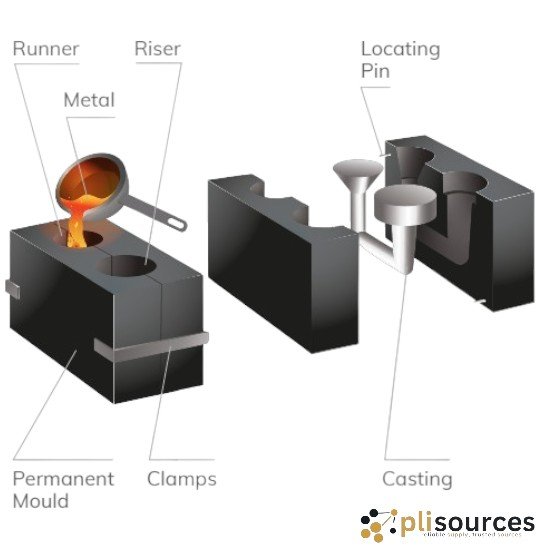

Understanding Aluminium Gravity Casting Process

Aluminium gravity casting is a manufacturing process in which molten aluminium is poured into reusable molds under gravity, resulting in high-quality components with exceptional structural integrity and durability. This method is particularly suited for moderate-volume production requiring precise, reliable outcomes. Steps: 1. The mould (die or tool) is preheated and coated with a suitable release agent to facilitate easy removal of the cast part. 2. Molten aluminium is poured into the mould through channels and runners, using either manual steel ladles or automated pouring methods, ensuring it fills all areas of the mould cavity thoroughly. 3. A specially designed "down sprue" allows the molten metal to enter the mould from the bottom, reducing turbulence and minimizing defects such as porosity and inclusions in the final product. 4. After sufficient cooling, the mould is opened manually or mechanically, and the solidified casting is safely removed. At Plisources, we provide seamless access to expert manufacturers specializing in aluminium gravity casting, ensuring dependable sourcing, consistent quality, and timely delivery to meet your project's specific requirements.