Introduction

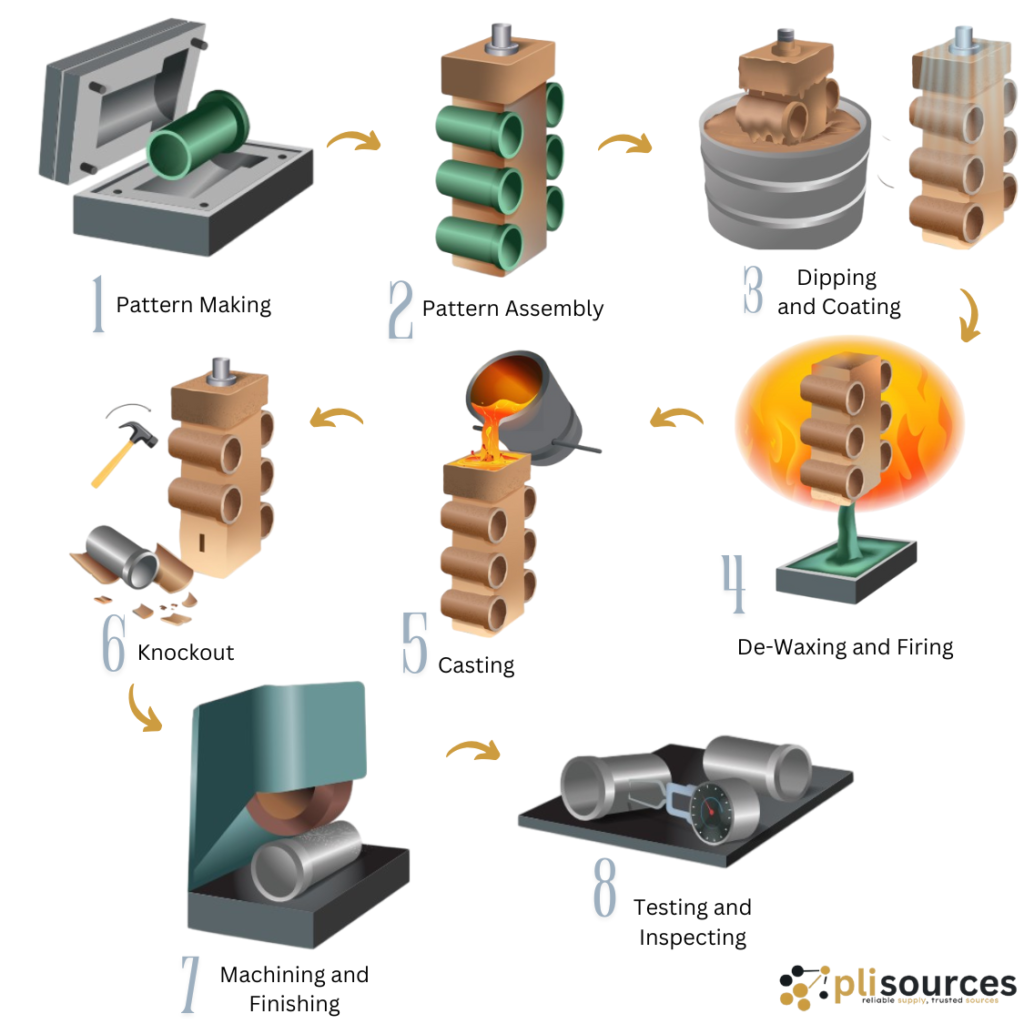

Understanding Investment Casting Process

We are proud to offer expert investment casting services, a precise and efficient method for metal casting. By pouring molten metal into high-quality ceramic molds, we specialize in producing high-quality, intricate components across a variety of metals, including iron, steel, aluminum, brass, and bronze. Our process is ideally suited for detailed productions that require exceptional accuracy and smooth finishes. Whether your needs include components for the aerospace, medical, automotive, or fine arts sectors, our investment casting solutions are designed to deliver superior precision quality.